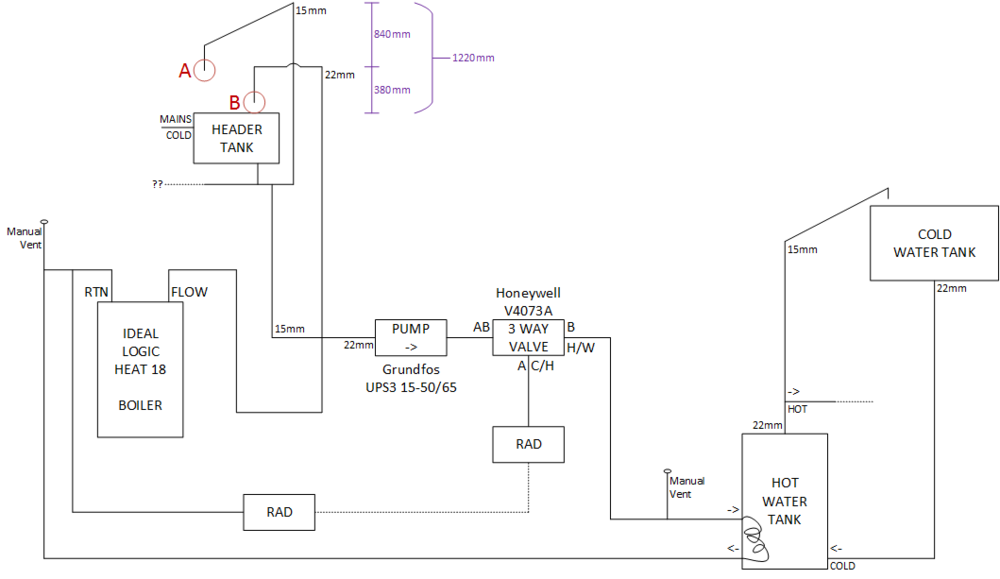

I have what I believe is a fairly standard open vented Y-plan heating system with a header tank and cold water tank in the loft (I have attached a picture of what I have worked out). I am not a plumber, but I am confident with pipe work - normally I would call a plumber but with the current COVID-19 crisis I don't want to risk it as I have a vulnerable person in the house who is isolating. A few days ago I had no CH or HW - the boiler wouldn't fire as it was reporting I had no water flow. I think the pump was at fault (a Grundfos Alpha 2L 15-60) as the lights were flickering and it was making no sound when it was being powered (normally it is quite noisy). I managed to source a new Grundfos UPS3 15-60/65 and replaced it like for like - I turned off the boiler, isolated the old pump from either side and replaced it - the arrow was pointing in the same direction (towards the 3 way value).

I initially turned the pump to 3 for 30 minutes as was directed in the instructions as it was supposedly self venting with both the CH and HW on - this resulted in a huge amount of air being drawn into the system - I then turned it down to the lowest setting. I have been bleeding radiators and manual air vents constantly for the past two days, but the amount of air isn't reducing and the boiler won't stay on for any period of time. I suspect due to the amount of air in the system. It turns on and fires then goes off after 30 seconds.

I am sometimes able to keep the boiler working if I turn on CH only, but I can still hear a lot of gurgling and air running around. As soon as I turn on HW then I can hear a lot more air gushing through the system and the boiler stops working. I am hearing a lot of gurgling coming from the 15mm vent pipe (A in the diagram) as well as hot water being expunged from the 22mm vent pipe (B in the diagram). The outlet pipework from the header tank is also boiling which implies there is back pressure somewhere (it also occasionally releases bubbles into the header tank).

I am looking for suggestions of where the problem might be and what I can try? I can live without CH at this time of year, but I really need to get the HW working.

I initially turned the pump to 3 for 30 minutes as was directed in the instructions as it was supposedly self venting with both the CH and HW on - this resulted in a huge amount of air being drawn into the system - I then turned it down to the lowest setting. I have been bleeding radiators and manual air vents constantly for the past two days, but the amount of air isn't reducing and the boiler won't stay on for any period of time. I suspect due to the amount of air in the system. It turns on and fires then goes off after 30 seconds.

I am sometimes able to keep the boiler working if I turn on CH only, but I can still hear a lot of gurgling and air running around. As soon as I turn on HW then I can hear a lot more air gushing through the system and the boiler stops working. I am hearing a lot of gurgling coming from the 15mm vent pipe (A in the diagram) as well as hot water being expunged from the 22mm vent pipe (B in the diagram). The outlet pipework from the header tank is also boiling which implies there is back pressure somewhere (it also occasionally releases bubbles into the header tank).

I am looking for suggestions of where the problem might be and what I can try? I can live without CH at this time of year, but I really need to get the HW working.