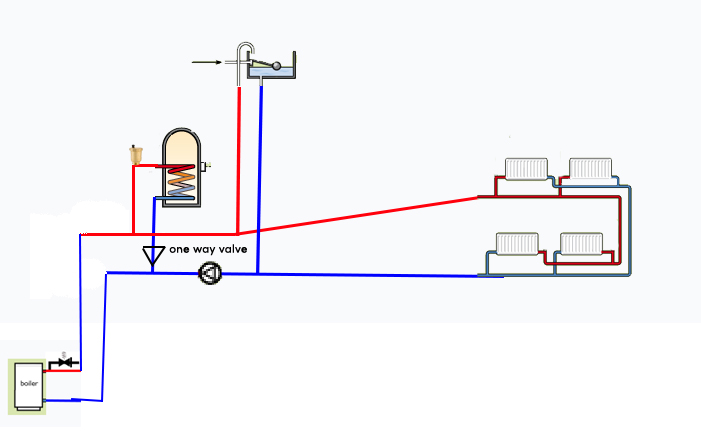

Hello i recently converted heating system from old stove to grand vortex b house 90 , boiler runs and works fine . How ever i have issue with water circulation have installed new pump but for some reason water don't circulate at all . what are the possible cause ? i have pump installed on return and and have one way valve on coil return I have attached image on how it looks like and schematics

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Thread starter egizz983

- Start date

- Replies 54

- Views 3K

- central central heating circulation heating issue

Discuss Central Heating circulation issue in the Central Heating Forum area at PlumbersForums.net

- Messages

- 34,369

- Solutions

- 2

Pump installed in the wrong place also shouldn’t be facing up the bleed screw needs to be on the side or at worst 45 degrees

- Messages

- 34,369

- Solutions

- 2

you mean on the other side of the T ? where should went be located then ?After the cylinder but your feed and vent arnt in the best position most likely will pump over

- Messages

- 34,369

- Solutions

- 2

As per my image also best to upgrade to an s plan from a gravity set up also while your at it eg port valves

based on that image would be best to put that pump on flow right after vent pipe pumping downwards ?As per my image also best to upgrade to an s plan from a gravity set up also while your at it eg port valves

Attachments

- Messages

- 34,369

- Solutions

- 2

So in the picture the right are the pipes straight from the boiler ?

no two pipes on the left traight from the boiler . pipes on the right is from atticSo in the picture the right are the pipes straight from the boiler ?

- Messages

- 34,369

- Solutions

- 2

So the left out the floor is the boiler ones

The ones on the right are to your rads ?

The ones on the right are to your rads ?

yes correctSo the left out the floor is the boiler ones

The ones on the right are to your rads ?

- Messages

- 34,369

- Solutions

- 2

Left hand side flow out the floor going upwards

Vent

Feed

Pump

Port valves for heating and hot water

If you want me to draw it out will knock something up tomorrow for you

Vent

Feed

Pump

Port valves for heating and hot water

If you want me to draw it out will knock something up tomorrow for you

yes if you could that would be greatLeft hand side flow out the floor going upwards

Vent

Feed

Pump

Port valves for heating and hot water

If you want me to draw it out will knock something up tomorrow for you

Yes and basicaly feed and expension pipe are the same . So if i understand this correctly best possition for he pump is on the flow right after t junction on downwards pipe that goes into rads and expansion pipe than would push water down then ?

Attachments

Last edited:

My 50 year old system has the exact same combined cold feed and vent but the pump is installed just before the (oil fired) boiler return on the ground floor.

A bit surprising, if the rad returns were into the pump suction that it wasnt circulating through the rads at least.

I think yes, install the pump on the flow side and ensure the cylinder flow and rads flow pipes are downstream of the pump discharge, assuming that you want to have a fully pumped CH&HW system. I would also suggest installing a 1/2" gate valve on the cold feed to the Feed&expansion tank ballcock filling line as you should fill the system very slowly so as the air can vent up through the same pipe that the water is filling the system through.

A bit surprising, if the rad returns were into the pump suction that it wasnt circulating through the rads at least.

I think yes, install the pump on the flow side and ensure the cylinder flow and rads flow pipes are downstream of the pump discharge, assuming that you want to have a fully pumped CH&HW system. I would also suggest installing a 1/2" gate valve on the cold feed to the Feed&expansion tank ballcock filling line as you should fill the system very slowly so as the air can vent up through the same pipe that the water is filling the system through.

Last edited:

I have moved pump to different location it seems to be working noe all fine . But the problem doest really heat hot water very well qnd forst floor radoators as well . Both flow and return pipes are hot now all rads on second floor also hot but hot water cylinder and first floor rads cold or at least it takes way longer to heat them up .

I see the pump is on Auto setting, you might change that to a higher setting and post the make/model of the pump, most pumps, Grundfos etc just don't work on this Auto setting. Also the cylinder coil NRV should be removed IMO (if still installed) especially if a spring loaded type but try pump on different setting for a start.

- Messages

- 34,369

- Solutions

- 2

port valves are essential ?should be installed like this

if i take off NRV then it stops circulating . i would guess i need to redo feed and pump location . Put pump on flow before boiler and feed before pump like in example ShaynCorbs sendI see the pump is on Auto setting, you might change that to a higher setting and post the make/model of the pump, most pumps, Grundfos etc just don't work on this Auto setting. Also the cylinder coil NRV should be removed IMO (if still installed) especially if a spring loaded type but try pump on different setting for a start.

- Messages

- 34,369

- Solutions

- 2

port valves are essential ?

Yes else your overheating / no control over hot water and hot water isn’t pumped

I would think that it should work if you install in the horizontal pipe just above it and shift the vent to the left of it, that way the cold feed is to the suction side of the pump and the whole system should operate at a positive pressure. As installed IMO, should still work but not the best as system will be at negative pressure in places.

Ideally, should have mot.valve and balancing valve on cylinder coil as cylinder temp will run at the boiler temperature otherwise.

Shaun is showing the pump on the flow from the boiler, pump pumping away from the boiler (correctly), but the above mod should achieve the same IMO.

Have you changed the pump settings?.

Ideally, should have mot.valve and balancing valve on cylinder coil as cylinder temp will run at the boiler temperature otherwise.

Shaun is showing the pump on the flow from the boiler, pump pumping away from the boiler (correctly), but the above mod should achieve the same IMO.

Have you changed the pump settings?.

Yes i tried to set to max but as soon as i take out NRV its stops circulating or atleast ot doest pump hot water from boiler though the system .I would think that it should work if you install in the horizontal pipe just above it and shift the vent to the left of it, that way the cold feed is to the suction side of the pump and the whole system should operate at a positive pressure. As installed IMO, should still work but not the best as system will be at negative pressure in places.

Ideally, should have mot.valve and balancing valve on cylinder coil as cylinder temp will run at the boiler temperature otherwise.

Shaun is showing the pump on the flow from the boiler, pump pumping away from the boiler (correctly), but the above mod shouachieve the same IMO.

Have you changed the pump settings?.

If the flow&return are as shown and directions correct and the cold feed is shown correctly then suggested mod should work IMO, there are hundreds of installations like this with the pump mounted high up at the cylinder some with a mid position valve close by. To get the system up and running you can always install the zone valve later but maybe install balancing valve with next mod. I don't have one (but do have a Mot.valve) and a 6M pump running at 3.5M can circulate 10 rads + the cylinder coil.

The most obvious question of all, are the flow and return pipes connected to the correct boiler points?.

I,m still a bit puzzled as to why the original installation (pump on return) didn't circulate through the rads as essentially it was the same as my system except that my pump is pumping into the boiler (return) at ground level and adjacent to the boiler, the cold feed is connected in exactly as yours is.

Two attic bedroom rads do run with a slight negative pressure but its never been a problem.

The most obvious question of all, are the flow and return pipes connected to the correct boiler points?.

I,m still a bit puzzled as to why the original installation (pump on return) didn't circulate through the rads as essentially it was the same as my system except that my pump is pumping into the boiler (return) at ground level and adjacent to the boiler, the cold feed is connected in exactly as yours is.

Two attic bedroom rads do run with a slight negative pressure but its never been a problem.

Attachments

Last edited:

- Messages

- 34,369

- Solutions

- 2

If the flow&return are as shown and directions correct and the cold feed is shown correctly then suggested mod should work IMO, there are hundreds of installations like this with the pump mounted high up at the cylinder some with a mid position valve close by. To get the system up and running you can always install the zone valve later but maybe install balancing valve with next mod. I don't have one (but do have a Mot.valve) and a 6M pump running at 3.5M can circulate 10 rads + the cylinder coil.

The most obvious question of all, are the flow and return pipes connected to the correct boiler points?.

I,m still a bit puzzled as to why the original installation (pump on return) didn't circulate through the rads as essentially it was the same as my system except that my pump is pumping into the boiler (return) at ground level and adjacent to the boiler, the cold feed is connected in exactly as yours is.

Two attic bedroom rads do run with a slight negative pressure but its never been a problem.

The pump is on the rad circuit only john

Original pump location (on the return) achieved no rad circulation, why not.

Second pump location only achieves limited rad circulation but only if cyl coil NRV installed, also strange.

Where should it be installed if my suggestion above incorrect?.

Second pump location only achieves limited rad circulation but only if cyl coil NRV installed, also strange.

Where should it be installed if my suggestion above incorrect?.

if i get this right i would need to move ether on return or flow but after or before boiler ,bypass valve . then have 3 way motorized valve that diverts either to cylinder or rads , and keep that NRV on return ? that would solve all problems i guess as it would heat up ether rads or cylinder first and then would switch to the other one . or ofc i 2x two way valves . but i though all this should work ether way without putting those 2 way valves as old houses dont have themOriginal pump location (on the return) achieved no rad circulation, why not.

Second pump location only achieves limited rad circulation but only if cyl coil NRV installed, also strange.

Where should it be installed if my suggestion above incorrect?.

on return . and behind cylinder there is two pipes going down straight to the stove , and another coil on the other side . So basically pipes on the right from rads was going behind boiler and down to the stove splitting into coil . So all i did basically is cut those pipes from stove and use the ones that on the left and new coil as well . its basically exactly how it was with the stove . Image on how it was and how it is nowWhere was the pump installed when you had the stove?

Last edited:

OK , thanks, clear now,

Was there any particular reason for installing the new circ pump on the return but upstream of the cyl coil return, which required the NRV on the coil return (post #1) when you could have installed the pump downstream of the cylinder coil return and have a fully pumped system and have removed the NRV and installed a gate valve for balancing purposes, if required?. I can now see why removing the coil NRV stopped all circulation with that setup.

OK , "Second pump location only achieves limited rad circulation but only if cyl coil NRV installed," this is possibly because the cold feed is to the pump flow side but really shouldnt stop circulation but if you are OK to do it, I would relocate the pump & AAV as per post #26 and install a balancing gate valve in place of the coil NRV and then test the system again, you can just use the gate valve as a on/off valve for the cylinder coil, if the results are satisfactory then can look at installing other options re zoning.

Can you give me details of that new circ pump, name/model etc.

Was there any particular reason for installing the new circ pump on the return but upstream of the cyl coil return, which required the NRV on the coil return (post #1) when you could have installed the pump downstream of the cylinder coil return and have a fully pumped system and have removed the NRV and installed a gate valve for balancing purposes, if required?. I can now see why removing the coil NRV stopped all circulation with that setup.

OK , "Second pump location only achieves limited rad circulation but only if cyl coil NRV installed," this is possibly because the cold feed is to the pump flow side but really shouldnt stop circulation but if you are OK to do it, I would relocate the pump & AAV as per post #26 and install a balancing gate valve in place of the coil NRV and then test the system again, you can just use the gate valve as a on/off valve for the cylinder coil, if the results are satisfactory then can look at installing other options re zoning.

Can you give me details of that new circ pump, name/model etc.

post 8 is photoshoped as a example on where to place pump . post #34 basicaly all you wrote is correct . Bottom pipe on the left is return from rads to the boiler . top pipe from the left is from boiler and on the right is feed and into the radiator flow . the reason i installed like this because i had no space on the left side return to install pump after the boiler . so i installed before and put that NRV. also i noticed that on post #34 where it says pump direction market against the flow is that an error ?I am seeing TWO pumps now in post #8, time for the Jamesons.

In post #1 you can see the arrow on the pump pointing towards the wiring on the pump terminal box, in post #34 unless you have changed the pump head orientation then the pump is pumping upwards, is the arrow on the pump pointing upwards or downwards.

post 8 is photoshoped as a example on where to place pump . post #34 basicaly all you wrote is correct . Bottom pipe on the left is return from rads to the boiler . top pipe from the left is from boiler and on the right is feed and into the radiator flow . the reason i installed like this because i had no space on the left side return to install pump after the boiler . so i installed before and put that NRV

in #1 picture thats where it was when i created the post and it was pumping to the left towards the boiler . but then Shaun said its in wrong location and i relocate based on picture on post #4 and now its pumping downwards . i rotate motor as well to original position . as in #1i had to rotate motor to move wire out of the way because doors was not closing , when moves upwards i moved back to original position . i can be confusing sometimes sorry #1 how it was #18 how it is now .In post #1 you can see the arrow on the pump pointing towards the wiring on the pump terminal box, in post #34 unless you have changed the pump head orientation then the pump is pumping upwards, is the arrow on the pump pointing upwards or downwards.

OK, thanks, that will work only on the rads as if/when you remove the cylinder coil NRV, the pump will be pulling on the coil hot pipe and the water from the coil cold pipe will then tend to be pulled in as well which will upset the whole circulation and no heat to the cylinder as well.

You could move the pump to before the coil hot pipe and you it will then circulate through the cylinder coil and the rads, only downside is that the cold feed will now be to the pump discharge and will result in negative pressure in parts of the system, you could then move the cold feed to the pump suction but better off with no horizontal runs which may be difficult to achieve or you could take a T from below the pump where its installed now and pipe that back into the coil flow (top) which may be the better option?

You could move the pump to before the coil hot pipe and you it will then circulate through the cylinder coil and the rads, only downside is that the cold feed will now be to the pump discharge and will result in negative pressure in parts of the system, you could then move the cold feed to the pump suction but better off with no horizontal runs which may be difficult to achieve or you could take a T from below the pump where its installed now and pipe that back into the coil flow (top) which may be the better option?

you mean like this ? the problem i would have this way that there would be not enough space to fit in pump unless i remove T and connect closer to vent going back to boiler flowI would think that it should work if you install in the horizontal pipe just above it and shift the vent to the left of it, that way the cold feed is to the suction side of the pump and the whole system should operate at a positive pressure. As installed IMO, should still work but not the best as system will be at negative pressure in places.

Ideally, should have mot.valve and balancing valve on cylinder coil as cylinder temp will run at the boiler temperature otherwise.

Shaun is showing the pump on the flow from the boiler, pump pumping away from the boiler (correctly), but the above mod should achieve the same IMO.

Have you changed the pump settings?.

Option B?, leave the pump where it is and run a pipe teed in below the pump (outlet) and connect directly into the coil HW inlet after removing the T and inserting a piece of pipe in the horizontal pipe. You should be ae to run it in a way to allow the installation of a motorised valve later for cylinder temperature control.

Could you make a drawing i didt really get what you meanOption B?, leave the pump where it is and run a pipe teed in below the pump (outlet) and connect directly into the coil HW inlet after removing the T and inserting a piece of pipe in the horizontal pipe. You should be ae to run it in a way to allow the installation of a motorised valve later for cylinder temperature control.

- Messages

- 34,369

- Solutions

- 2

Or just move the pump to the left and pipe up how I drew it

so i think your drawing is exactly how John drew in #43 i think . only thing is vent is in wrong position but does that effect anything ?"Or just move the pump to the left and pipe up how I drew it

- Messages

- 34,369

- Solutions

- 2

so i think your drawing is exactly how John drew in #43 i think . only thing is vent is in wrong position but does that effect anything ?"

If you look the vent is moved as well

So if i do like John in that image i would need to put another T under flow to coil for vent . right ? does vent location make big impact on heating system ?If you look the vent is moved as well

Would i remove NRV then ?What about this?, should work??

- Messages

- 34,369

- Solutions

- 2

Need to move the vent

You have a combined Vent and cold feed, one vertical pipe in effect, it should connect into the system on the suction side of the pump, reason is, when connected to the suction side, the pump suction will be at the elevation head (height) from the F&E tank surface to the pump suction, say 1.5M or whatever, the pump discharge head will then be pump head + the elevation head, a pump head of say 3.5M+1.5M=5M, all the system at positive pressure. If connected at the pump discharge the pump discharge head will be 1.5M and the pump suction, 1.5M - 3.5M, a negative head of 2M, most of the system under nrgative pressure.So if i do like John in that image i would need to put another T under flow to coil for vent . right ? does vent location make big impact on heating system ?

So if you go for the first option you just move this vertical pipe to the left of the pump after also moving the pump as per your own post #40 and thats it. If you go for option 2, my post #43, then the vertical pipe is already to the pump suction and you run the pipe as shown to the cylinder HW inlet.

There is a plasic 1/2" pipe above the combined vent&cold feed, where does that go to? or is it removed and capped somewhere below?. Or ist blanked off and removed at the tank?.

Looks like the mains supply to the ballcock??.

You don't have to but its better to do so and replace it with a gate valve for balancing purposes and before you install (if) a motorized valve you can simply use the gate valve as a cylinder temperature control, on/off or whatever.Would i remove NRV then ?

Attachments

Last edited:

Reply to Central Heating circulation issue in the Central Heating Forum area at PlumbersForums.net

Similar plumbing topics

I am sizing the central heating pipes for a complete replacement. The property has an elongated floor plan so I have used a piping layout...

- Replies

- 2

- Views

- 1K

Hello,

I live in a two floor semi with a gravity fed conventional gas fired boiler (Potterton Kingfisher MF). The boiler is fed cold water from...

- Replies

- 0

- Views

- 527

Hi,

Over the past few months, my wife and I have noticed a constant pulsing sound throughout the house which is particularly noisy at night (this...

- Replies

- 4

- Views

- 685

Can central heating / gas engineer expert help me with below issue.

During winter time only, I have been having issue with low pressure or...

- Replies

- 0

- Views

- 616

Hi, I have a Worcester 28i junior boiler that has started to lose pressure, only when using the central heating. When using hot water I have no...

- Replies

- 6

- Views

- 301

Newest Plumbing Threads

-

-

Y Plan central heating gets hot on hot water demand

- Started by MPGASANDPLUMBING

- Replies: 0

-

Grant boiler rusting inside after 1 yr

- Started by RayPlumb

- Replies: 10

-

Instructions say to apply glass cement to rubber washer. Can I use silicone?

- Started by JM Tiling

- Replies: 2

-

How do I remove the copper pipe from the plastic connector?

- Started by JM Tiling

- Replies: 2

-

Pressure reducer/regulator for plastic water line?

- Started by carpetguardian

- Replies: 1

-

Cold water issues in the top bathroom

- Started by Apex84

- Replies: 3