N

Nordio

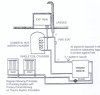

5.3.5.6.1Vented primary circuits

Vented primary circuits shall have a vent route connecting the flow connection on the boiler to the vent pipe outlet above the expansion cistern and a feed water route from a point near the bottom of the expansion cistern to the return connection on theboiler.

Except as specified in this subclause, these routes shall be independent. It is permissible for both these routes to be incorporated in parts of the primary flow and return pipework, but the vent route shall not include any valve, pump or any impediment to flow whatsoever.

Where the design of the primary circuit so dictates, it is permissible to include a circulating pump and its associated isolating valves in the feed water route. A feed and expansion cistern for a double feed primary circuit shall accommodate 4% expansion of the volume of the water inthe circuit. Except for a circulating pump and its associated isolating valves and except for a servicing valve, both fitted only in the circumstances specified in this sub clause, the feed water route shall not include any valve, pump or any impediment to flow what so ever. Where the vent route and water route are combined, the boiler and primary circuit shall have the protection specified in 5.4.

Does the part highlighted in bold mean its ok to have a circulating pump in the feed water route?

Its a solid fuel system and I want to stay within the regs but intrepeting these are a bit confusing.

Can anyone shed any light on the subject?

Thanks.

Vented primary circuits shall have a vent route connecting the flow connection on the boiler to the vent pipe outlet above the expansion cistern and a feed water route from a point near the bottom of the expansion cistern to the return connection on theboiler.

Except as specified in this subclause, these routes shall be independent. It is permissible for both these routes to be incorporated in parts of the primary flow and return pipework, but the vent route shall not include any valve, pump or any impediment to flow whatsoever.

Where the design of the primary circuit so dictates, it is permissible to include a circulating pump and its associated isolating valves in the feed water route. A feed and expansion cistern for a double feed primary circuit shall accommodate 4% expansion of the volume of the water inthe circuit. Except for a circulating pump and its associated isolating valves and except for a servicing valve, both fitted only in the circumstances specified in this sub clause, the feed water route shall not include any valve, pump or any impediment to flow what so ever. Where the vent route and water route are combined, the boiler and primary circuit shall have the protection specified in 5.4.

Does the part highlighted in bold mean its ok to have a circulating pump in the feed water route?

Its a solid fuel system and I want to stay within the regs but intrepeting these are a bit confusing.

Can anyone shed any light on the subject?

Thanks.

Last edited by a moderator: