Hi all,

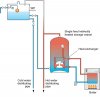

We are currently renovating an old property in the centre of Lincoln. The owner is adamant they don't want to replace the existing floor standing boiler as long as it's safe. We are replacing the existing indirect vented hot water cylinder with a larger one of the same type. There is currently an open vent on the hot water system in 15mm so we will be upgrading that to 22mm. There is no open vent on the CH system so we will be running one off the primary coil return. There is a cold feed in 15mm to the system obviously but this goes into the wall and we're not sure where it tees into the system. Does anyone have any ideas where it's likely to tee in as I would like to connect it in on the primary coil flow in preparation for converting the system over to a fully pumped S plan system. Only ever seen cold feed pipes connecting into the coil flow in the airing cupboard before and don't want to take the house apart to find it really!

We are currently renovating an old property in the centre of Lincoln. The owner is adamant they don't want to replace the existing floor standing boiler as long as it's safe. We are replacing the existing indirect vented hot water cylinder with a larger one of the same type. There is currently an open vent on the hot water system in 15mm so we will be upgrading that to 22mm. There is no open vent on the CH system so we will be running one off the primary coil return. There is a cold feed in 15mm to the system obviously but this goes into the wall and we're not sure where it tees into the system. Does anyone have any ideas where it's likely to tee in as I would like to connect it in on the primary coil flow in preparation for converting the system over to a fully pumped S plan system. Only ever seen cold feed pipes connecting into the coil flow in the airing cupboard before and don't want to take the house apart to find it really!

Last edited: