Hi all - hopefully I can get some answer to a maddening issue. The boiler bypass just refuses to stop letting water through.

Here is the run down. We bought the house last year. It has a Vaillant Ecotec Plus 418 which is only 3 years old. It's on a Y plan, with a hot water cylinder that looks to have been installed at the same time as the boiler - it's very new and a sealed foam type.

When we moved in we had new rads all round and all the microbore removed. The system was powerflushed thoroughly.

The 3 way valve was replaced as it had seized so that's new and works fine.

The pump is a Grundfos Alpha2 15-60 130.

The hot water tank thermostat was not working so was replaced (and works fine).

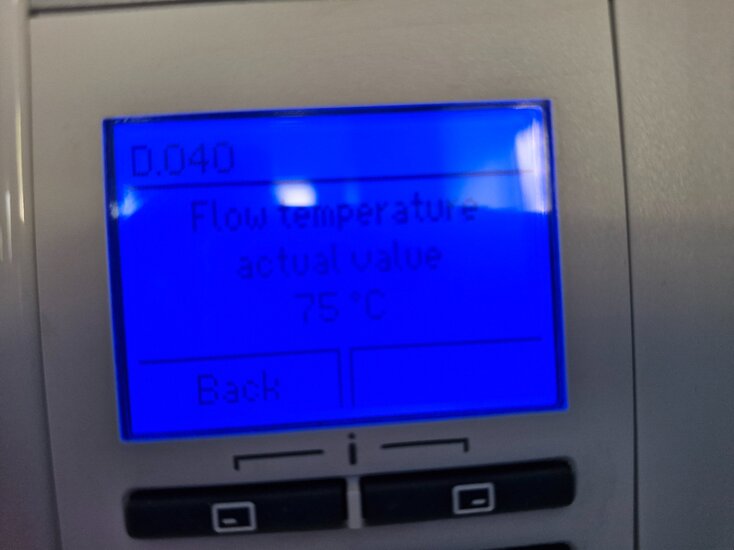

The whole heating system works well but it's very slow to heat the hot water tank - sometimes over 2 hours, and the boiler keeps going into S46 - Comfort protection, loss of flame.

There is a 15mm bypass from the exit of the pump to the return which had a tacosetter on it set to 11l/h (presumably because the boiler min flow is 10.5).

This has now been replaced with a straight auto bypass which ranges from 0.1 to 0.5 bar.

The ch system has 2 towel rails on it which are always open, and the pump is level with the highest rad. It's a 2 story house, open system with a tank in the roof about 3m above the pump.

Even with the hot water tank calling for heat and the ch circuit on (3 way valve on 'mix') the bypass is still open. It's a brand new valve. This occurs whether the pump is ramped all the way up to 45w or tricking along at 11w. On pp1, or pp2, or even auto (which gives the lowest power) of fixed at I, II or II it's the same.

It makes no sense. Even with ch and hw calling for heat, a good few trvs open and the 2 towel rails, and the pump on its minimum setting, water is still getting though the bypass even if it's ramped all the way up to 0.5 bar.

I have tried running the pump at 45w and shutting off the stopcocks to the ch and hw tank to force water though the bypass at a good rate in case it was blocked by something, but no solution.

Any ideas?

Here is the run down. We bought the house last year. It has a Vaillant Ecotec Plus 418 which is only 3 years old. It's on a Y plan, with a hot water cylinder that looks to have been installed at the same time as the boiler - it's very new and a sealed foam type.

When we moved in we had new rads all round and all the microbore removed. The system was powerflushed thoroughly.

The 3 way valve was replaced as it had seized so that's new and works fine.

The pump is a Grundfos Alpha2 15-60 130.

The hot water tank thermostat was not working so was replaced (and works fine).

The whole heating system works well but it's very slow to heat the hot water tank - sometimes over 2 hours, and the boiler keeps going into S46 - Comfort protection, loss of flame.

There is a 15mm bypass from the exit of the pump to the return which had a tacosetter on it set to 11l/h (presumably because the boiler min flow is 10.5).

This has now been replaced with a straight auto bypass which ranges from 0.1 to 0.5 bar.

The ch system has 2 towel rails on it which are always open, and the pump is level with the highest rad. It's a 2 story house, open system with a tank in the roof about 3m above the pump.

Even with the hot water tank calling for heat and the ch circuit on (3 way valve on 'mix') the bypass is still open. It's a brand new valve. This occurs whether the pump is ramped all the way up to 45w or tricking along at 11w. On pp1, or pp2, or even auto (which gives the lowest power) of fixed at I, II or II it's the same.

It makes no sense. Even with ch and hw calling for heat, a good few trvs open and the 2 towel rails, and the pump on its minimum setting, water is still getting though the bypass even if it's ramped all the way up to 0.5 bar.

I have tried running the pump at 45w and shutting off the stopcocks to the ch and hw tank to force water though the bypass at a good rate in case it was blocked by something, but no solution.

Any ideas?