I have today tried to replace the bottom immersion heater on an Economy 7 direct hot water cylinder but ended up with a major problem.

The heater element came out relatively easily part from being quite stiff to undo which I put down to the age of the cylinder.

I removed the old heater element, cleaned the thread and removed all the gunk/dirt from the mating surface for the new immersion.

I then tried the new immersion in the thread, gave it about half a turn without any problem then removed it to apply the gasket and some

FERNOX LX to the mating surfaces for good measure.

However, I then tried to put the new immersion back into the cylinder but could not locate it on the thread to get it going.

After several attempts, it went into the thread but would only go about 1 1/2 turns and then binded

with still along way to go before it would have been water tight. I struggled with it for about 10 minutes, removed it and tried the old element which

went in about 2 1/2 turns before again binding well before the fibre washer was touching the cylinder.

After about an hour and a half (should be a 15 minute job max) of trying the get the new immersion into the thread I gave up.

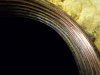

The new immersion will just not turn fully into the thread not matter how many times I try and neither will the old one. The thread looks fine with

no obvious signs of cross threading but even an immersion blank plate wouldn't go fully into the thread either.

Does anyone please have any suggestions how I can resolve this ?

Thank you

The heater element came out relatively easily part from being quite stiff to undo which I put down to the age of the cylinder.

I removed the old heater element, cleaned the thread and removed all the gunk/dirt from the mating surface for the new immersion.

I then tried the new immersion in the thread, gave it about half a turn without any problem then removed it to apply the gasket and some

FERNOX LX to the mating surfaces for good measure.

However, I then tried to put the new immersion back into the cylinder but could not locate it on the thread to get it going.

After several attempts, it went into the thread but would only go about 1 1/2 turns and then binded

with still along way to go before it would have been water tight. I struggled with it for about 10 minutes, removed it and tried the old element which

went in about 2 1/2 turns before again binding well before the fibre washer was touching the cylinder.

After about an hour and a half (should be a 15 minute job max) of trying the get the new immersion into the thread I gave up.

The new immersion will just not turn fully into the thread not matter how many times I try and neither will the old one. The thread looks fine with

no obvious signs of cross threading but even an immersion blank plate wouldn't go fully into the thread either.

Does anyone please have any suggestions how I can resolve this ?

Thank you