If it comes to fitting a flange you will have to drill the old one out and file it into shape (it is easier done than it sounds). You won't be able to hacksaw it. We used to use a tool called a monodex cutter to fit these but in this instance even that wouldn't work so you are left with the drill and file method.

Because this is the type of guy i am, i went out to the yard (in my house coat in the baltic cold) and sourced (rumadged for) an old essex flange. These instructions are probably older than you because i have had them for years but here they are.

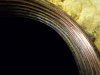

View attachment 5328

The link above was the only one i could find on google but you would be able to order one from a merchant.

Take your time. It can be fixed with a bit patience and the flange is your fall back.

There are other ways to do this but they are too hard to explain. It is something you need to be shown to understand.

Good luck. Take your time and you will get there.