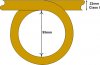

I need to bend a 22mm class I pipe into a full 360 degree turn. I need the inside diameter of the bend to be a nominal 95mm. I'm hoping to avoid making up specific tooling because of the expense and wondered if anyone had any ideas how I might do it.

I have available a standard plumbing type 15/22mm pipe bender which will produce a finished radius of about 100mm so it's a starting point at least. I also have some bending springs and the usual general workshop tools. Any thoughts greatly appreciated.

I have available a standard plumbing type 15/22mm pipe bender which will produce a finished radius of about 100mm so it's a starting point at least. I also have some bending springs and the usual general workshop tools. Any thoughts greatly appreciated.