G

garmcqui

Hi all,

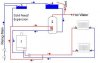

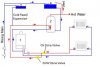

I'm planning a mild upgrade my parents old gravity fed (fully pumped) oil-fired central heating system over Easter. The current setup is rather strange - "non standard" shall we say? This is a rough mock-up of the current plumbing setup:

Notice there is no open vent pipe, just a combined cold feed and expansion pipe, which is attached on the positive side of the pump to the feed pipe to hot water cylinder! Not ideal, I think you'll agree.

Currently there is no control whatsoever, just "on/off". I'm planning on adding a Honeywell wireless programmable thermostat, changing all radiators to TRV's (except in the living room where the thermostat will be) and adding a couple of zone valves so DHW and CH can be turned on independently of one another (currently they are both on or both off). I will also put an automatic bypass valve in.

TRV'ing the rads is fine, as is setting up the thermostat etc. However, placement of zone valves is perplexing me. With the lack of vent, I understand I have to be careful not to isolate the feed/expansion if one or both of the valves are closed.

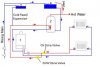

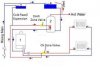

I had originally intended to place the zone valves here (indicated by yellow boxes):

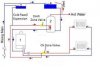

However, in order to avoid isolating the feed/expansion pipe, perhaps I should site the DHW zone valve here instead:

Or would that still not work?

Any advice appreciated.

Thanks

I'm planning a mild upgrade my parents old gravity fed (fully pumped) oil-fired central heating system over Easter. The current setup is rather strange - "non standard" shall we say? This is a rough mock-up of the current plumbing setup:

Notice there is no open vent pipe, just a combined cold feed and expansion pipe, which is attached on the positive side of the pump to the feed pipe to hot water cylinder! Not ideal, I think you'll agree.

Currently there is no control whatsoever, just "on/off". I'm planning on adding a Honeywell wireless programmable thermostat, changing all radiators to TRV's (except in the living room where the thermostat will be) and adding a couple of zone valves so DHW and CH can be turned on independently of one another (currently they are both on or both off). I will also put an automatic bypass valve in.

TRV'ing the rads is fine, as is setting up the thermostat etc. However, placement of zone valves is perplexing me. With the lack of vent, I understand I have to be careful not to isolate the feed/expansion if one or both of the valves are closed.

I had originally intended to place the zone valves here (indicated by yellow boxes):

However, in order to avoid isolating the feed/expansion pipe, perhaps I should site the DHW zone valve here instead:

Or would that still not work?

Any advice appreciated.

Thanks

Last edited by a moderator: